India has taken a decisive step toward strengthening its sovereign aero-engine capability. The Gas Turbine Research Establishment (GTRE), Bengaluru, under the Defence Research and Development Organisation (DRDO), has formally issued an Expression of Interest (EoI) to identify a Development-cum-Production Partner (DcPP) for the manufacturing and assembly of an Indigenous Advanced High Thrust Class Aero Engine (AHTCE). This programme is aimed at establishing a long-term industrial ecosystem capable of supporting the full lifecycle of advanced military aero gas turbine engines.

The initiative is being pursued in collaboration with an international engine house while ensuring that design ownership, manufacturing depth, and sustainment capability are progressively indigenised. GTRE’s approach reflects a strategic shift from laboratory-centric development to an industry-anchored national propulsion base.

Strategic Context and Programme Vision

GTRE has been at the core of India’s military aero-engine research. With the AHTCE programme, DRDO intends to create not just an engine, but a national capability spanning design translation, precision manufacturing, system integration, qualification, and long-term support. The EoI explicitly seeks Indian defence and aerospace firms capable of executing complex system programmes under stringent airworthiness and certification regimes.

The DcPP will act as the primary industrial execution agency, responsible for transforming GTRE’s engineering outputs into flight-worthy hardware. This includes tooling, manufacturing engineering, special processes, inspection systems, engine assembly, subsystem testing, and final integration.

Scope of the Indigenous High Thrust Engine Programme

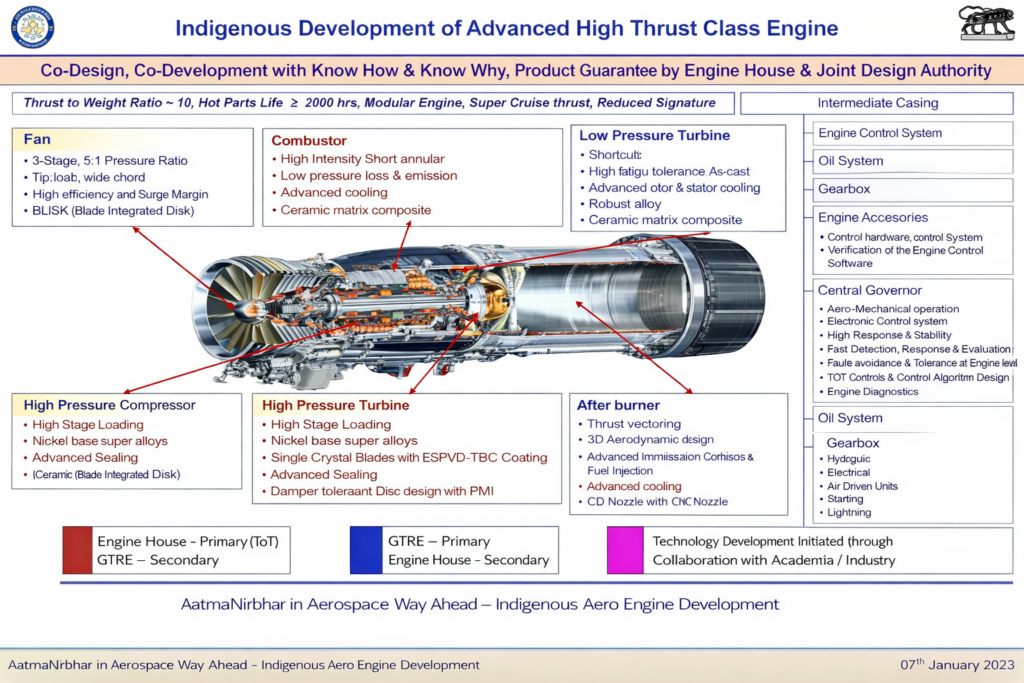

The proposed engine covers the full spectrum of a modern turbofan architecture. The scope includes manufacturing and assembly of major turbomachinery modules such as the low-pressure compressor, high-pressure compressor, combustor, high-pressure turbine, low-pressure turbine, exhaust cone, afterburner, rotor support systems, and exhaust nozzle. It also includes accessories and critical subsystems like the gearbox, oil system, fuel system, actuators, and FADEC integration units.

The programme involves development and delivery of 18 complete engines over a 10-year horizon, along with nearly 2,300 components, sub-assemblies, and assemblies. The intent is to progressively mature the industrial partner’s ability from component manufacturing to complete engine build-up, validation, and sustainment.

Multi-Phase Execution Model

GTRE has defined a four-phase execution structure, ensuring that capability buildup occurs in a controlled and auditable manner.

1. Design Phase

The DcPP will support GTRE through detailed engineering, preparation of 2D drawings, 3D models, design iterations, and configuration updates based on test feedback. The partner must deploy skilled design, analysis, and manufacturing engineering teams at GTRE and its own facilities. Tooling concepts, manufacturing routings, and special process definitions are integral parts of this phase.

2. Manufacturing Planning Phase

This phase focuses on process engineering and industrial readiness. The DcPP must develop master process sheets, digital mock-ups, assembly layouts, inspection strategies, and resource loading plans. Special processes must be aligned with NADCAP-approved standards, and all infrastructure must be mapped to aero-engine quality management systems.

3. Manufacturing Phase

The DcPP will manufacture components, sub-assemblies, and modules, including raw material procurement, bought-out item management, first-article inspection, non-destructive testing, and dimensional validation. This phase also includes inspection planning, statistical quality controls, and subsystem-level validation.

4. Assembly and Integration Phase

This is the core industrial responsibility. The DcPP must establish engine assembly bays, develop build sequences, balancing procedures, instrumentation layouts, and test readiness. The partner is required to conduct module integration, rotor balancing, subsystem testing, and final engine build-up in coordination with GTRE and certification agencies.

Roles and Institutional Framework

GTRE remains the design authority and programme owner. It provides engineering data, materials support, instrumentation philosophy, and coordination with airworthiness agencies.

The DcPP becomes the industrial execution authority, responsible for:

- Production engineering and industrialisation

- Tooling, fixtures, and assembly systems

- Subsystem manufacturing and integration

- Quality assurance and configuration control

- Coordination with CEMILAC, DGAQA, and TAA for certification

- Documentation, traceability, and life-cycle data management

The framework integrates GTRE, the international engine house, certification agencies, and the industrial partner into a structured national propulsion ecosystem.

Infrastructure and Technology Depth Required

The EoI specifies extensive critical manufacturing and inspection infrastructure. This includes multi-axis CNC machining for large blisks and casings, high-precision EDM, electron beam welding, laser processing, advanced coatings, heat treatment, and vacuum furnaces.

Special processes explicitly listed include thermal barrier coatings, plasma spraying, EB-PVD, vacuum brazing, diffusion bonding, nitriding, carburising, and powder metallurgy, all to be qualified under NADCAP or equivalent regimes.

Inspection systems must cover CMMs with turbine-class accuracy, ultrasonic testing, radiography, eddy current inspection, fluorescent penetrant testing, hardness testing, and surface metrology. This underlines that the DcPP is not a build-to-print vendor but a full-spectrum aero-engine manufacturing house.

Engine Delivery Roadmap

The document defines a structured engine delivery schedule. Initial deliveries begin around the seventh year after contract signature, gradually ramping up to multiple engines per year. This slow-build philosophy reflects the complexity of propulsion industrialisation and the need to stabilise quality, repeatability, and certification confidence.

Production and Long-Term Support Vision

Although not part of the immediate DcPP contract, the Ministry of Defence signals intent to later place a separate production order for up to 200 engines. The selected DcPP must formally consent to supporting serial production, integrated logistics, and product support for the full operational life of the engine.

This positions the AHTCE programme not as a prototype effort, but as the foundation of a future Indian military engine production line.

Evaluation and Eligibility Framework

The DcPP selection is based on five evaluation pillars: financial, technical, manufacturing, assembly and inspection infrastructure, and special process approvals. Only Indian companies from the defence or aerospace sector with proven aero-engine or turbomachinery experience are eligible.

Financially, firms must demonstrate strong consolidated turnover, net worth, revenue growth, and stable credit ratings. Technically, they must show experience in titanium, nickel alloys, advanced composites, and high-precision aerospace manufacturing.

The EoI also mandates documented quality systems aligned with AS9100, AQMS, and national airworthiness frameworks.

Intellectual Property and Control

All intellectual property generated under the programme remains under the ownership of the Government of India or jointly with the Development Partner, as determined by DRDO-GTRE. The partner may receive restricted manufacturing rights for series production but does not gain independent commercial ownership of the engine design.

This structure protects sovereign control over propulsion technology while enabling private industry to build long-term industrial competence.

Strategic Significance

The AHTCE DcPP programme is one of the most comprehensive industrial propulsion initiatives launched by DRDO to date. It reflects a shift from import-dependence mitigation to indigenous capability creation, covering not only engines but the full supply chain: materials, processes, inspection, digital manufacturing, assembly engineering, and sustainment.

By mandating deep manufacturing and assembly responsibility, GTRE is forcing the emergence of at least one Indian private-sector entity capable of standing alongside global aero-engine majors in infrastructure and execution capability.

Overall, The GTRE EoI for an Indigenous Advanced High Thrust Class Aero Engine represents a structural inflection point in India’s aerospace journey. It transforms propulsion from a laboratory pursuit into a national industrial mission. The chosen DcPP will not merely build engines; it will help establish India’s first truly comprehensive military aero-engine production ecosystem.

If executed as envisioned, this programme will determine whether India can finally close the most critical gap in its aerospace sovereignty.

I have read the narration of the whole projet about GTRE-DRDO Kick Starting development of Desi High thrust Jet Engine.

It’s quite elaborate,well thoughtout in terms of being perspective and envisaging of involvement of both Government and Private Competent

Enterprise.Execution, reviewing on continuing basis and employing mid course correction by inclusion of newer technological advances achieved elsewhere by judiciously evaluation in conjuction of intended goal would be desired as it would creat dynamic Indian Ecosystem in this sector of technology.

Men, material,technology may evolve continuously however our philosophy must be progressively steadfast,no matter whichever political party is governing the country. This is a National Project which must be adopted gradually in all walks of Economy.

just make 90 KN max. wet thrusts engine to replace ge f404 one’s for now!!!!

There’s no mention abot external/overall size restrictions (not necessarily the classified information but just a mention).

Secondly, there’s no mention about dry/wet thrust output.

Then, finally about the application side including the marine ones. I’m also curious to know whether this initiative can help to develop the Civilian aero engines as well!

Let’s first them develop the core engine itself. Pretty sure after that Marine, industrial & civilian sector will be naturally proceed.

I hd also read HAL Safran is developing aero engine, then won’t it be a duplication of efforts