The Indian Navy has taken a major stride toward achieving self-reliance in propulsion technology with the launch of its 24-28 MW Indigenous Gas Turbine Marine Engine Development Program. The Approval in Principle was given on 28th July 2025. This initiative is a landmark under the ‘MAKE-I’ category of DAP 2020, signifying the Navy’s strong commitment to indigenization in high-technology sectors.

Breaking Dependence on Imports

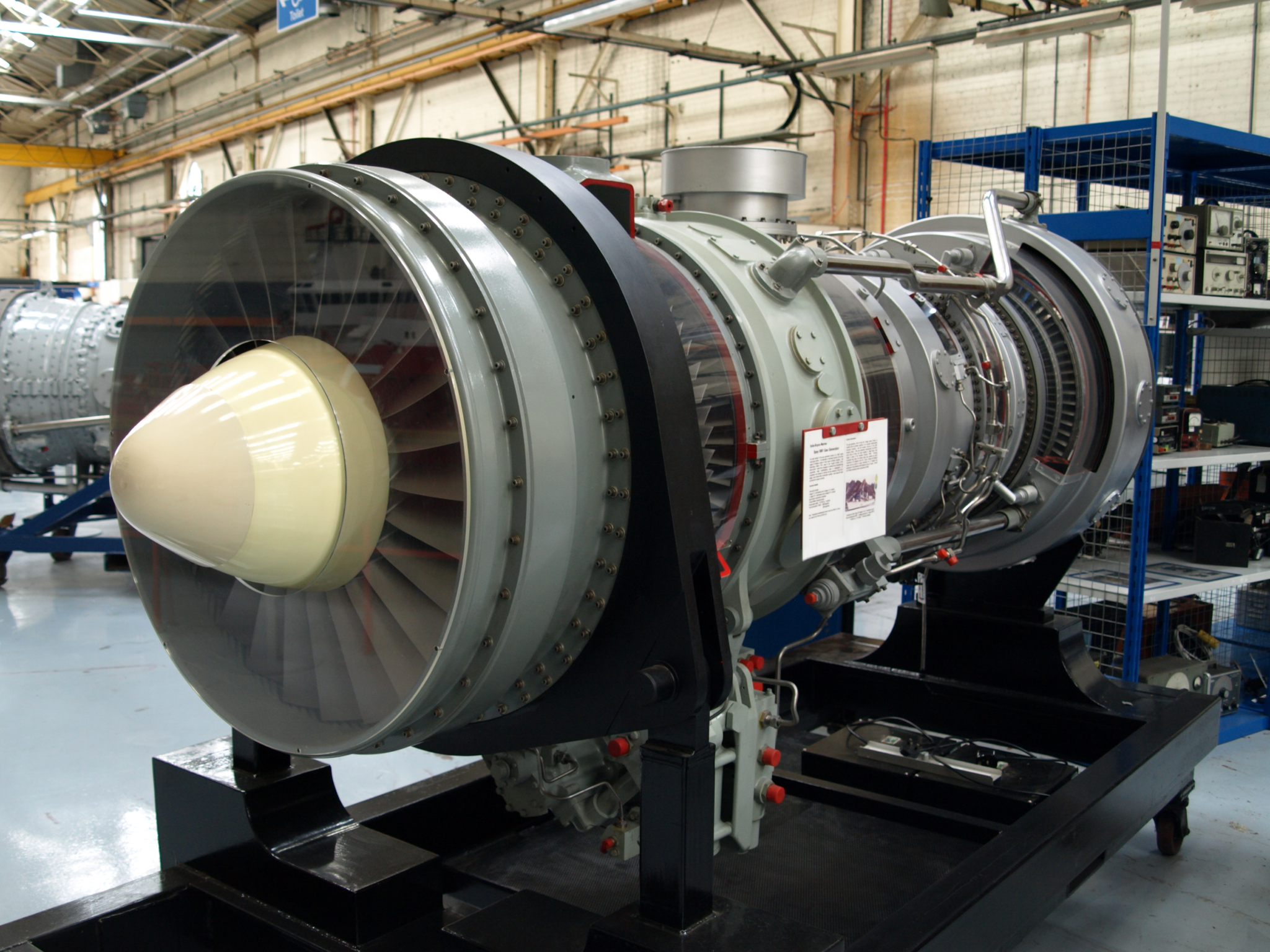

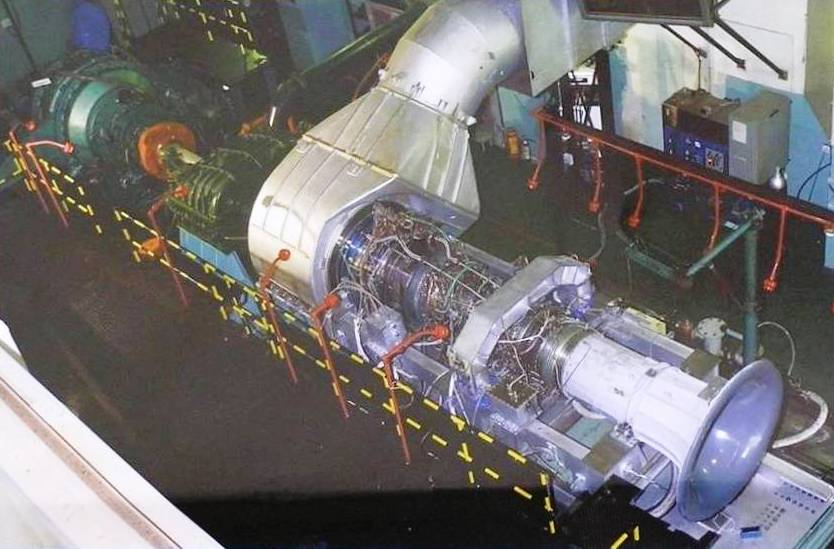

For decades, the Indian Navy has relied heavily on imported marine gas turbines to power its frontline warships. Engines like the Zorya-Mashproekt (Ukraine) and General Electric LM2500 (USA) have been mainstays of naval propulsion. It has also actively participated in the indigenous effort for the Kaveri Marine Gas Turbine (KMGT) with GTRE, Bengaluru covering design, development, production, and testing. Additionally, localization was pursued through HAL-GE and BHEL-ZM collaborations involving transfer of technology. However, the aforementioned approaches have not yielded desired results.

The indigenous program aims to design and develop 24–28 MW class marine gas turbine engines, specifically tailored to Indian naval requirements.This power range is crucial for destroyers, frigates, and future large surface combatants that require high endurance, reliability, and rapid acceleration capabilities.

Strategic Significance

1. Operational Independence : Eliminating reliance on foreign OEMs ensures uninterrupted availability of critical propulsion systems.

2. Cost Efficiency : Indigenous production reduces long-term procurement and maintenance costs.

3. Technology Leap : Development of high-thrust marine gas turbines requires advanced materials, precision engineering, and high-temperature metallurgy. All of which will enhance India’s overall aerospace and defence ecosystem.

4. Export Potential : Success in this program could open new markets in friendly navies across the Indian Ocean Region (IOR) and beyond.

The Development Roadmap

1. Prototype Phase : Four prototypes will be developed for extensive testing and evaluation.

2. Bulk Production : Following validation, a minimum order quantity of 40 engines is earmarked for induction into naval platforms.

3. Technology Partners : Public Sector Undertakings (PSUs) such as HAL and BHEL, alongside private industry leaders and R&D institutions like GTRE (Gas Turbine Research Establishment, DRDO), are expected to play pivotal roles.

Challenges Ahead

Indigenous gas turbine development is one of the most complex engineering challenges. High-pressure ratios, advanced cooling techniques, blade metallurgy, and efficient fuel consumption must all be mastered to meet global benchmarks. Additionally, naval engines face harsher operating conditions than their aviation counterparts due to corrosive marine environments.

In the coming decade, the success of this initiative could transform India into one of the few countries globally with the ability to design and produce world-class marine gas turbines, cementing its position as a leading maritime power.

India is a major power and every powerful country must have own technology, design , manufacturing and ownership. outsourcing technology is dependence on others.

Tech squeeze on India has started once again. I can foresee multiple attacks on India on every front, internal, external, economic, cultural, etc.

“If I’d learnt one thing from travelling, it was that the way to get things done was to go ahead and do them. Don’t talk about going to Borneo. Book a ticket, get a visa, pack a bag, and it just happens.” –