A user on X recently asked me what I would do differently if I were in charge of the Advanced Medium Combat Aircraft (AMCA) program. The real challenge is not about introducing something completely new. Instead, it is about ensuring that everything happens within a strict timeline. India has already gained expertise in fighter jet manufacturing through the Light Combat Aircraft (LCA) program. Now, the focus should be on making the AMCA program more agile and refining it during prototyping. As my doctoral guide used to say, “Don’t let the best be the enemy of the good.”

The Ministry of Defence has proposed a new manufacturing model for the AMCA. This model will create a consortium where Hindustan Aeronautics Limited (HAL) will hold 50% of the stakes, while four work-package owners will hold 12.5% each. To improve this plan, I propose a structured approach that ensures faster development while addressing technical and industrial challenges.

1. Enhancing Manufacturing Technology

Strengthening Workforce Skills

India must enhance its aerospace manufacturing technology to keep pace with global standards. A Technology Readiness Acceleration Program should train Indian Air Force officers, HAL engineers, and Defence Research and Development Organisation (DRDO) scientists. This program should focus on:

- Additive manufacturing

- Friction stir welding

- Artificial intelligence-driven quality control

- Digital twins

- Model-based systems engineering

Industry-Academia Collaboration

India should build an embedded industry-academia knowledge transfer ecosystem. Collaborations with global leaders like Lockheed Martin, Boeing, BAE Systems, and Dassault Aviation can accelerate learning. This ecosystem will help engineers and scientists adopt best practices from experienced aerospace firms.

Smart Manufacturing

Implementing a Manufacturing 4.0 Playbook can optimize production. This strategy should include:

- Real-time monitoring

- Predictive maintenance

- Seamless supply chain integration using Internet of Things (IoT)-enabled production systems

2. Prioritizing System Capabilities

Categorizing Subsystems

India must classify AMCA’s components based on their importance. This method ensures a strategic allocation of resources. The classification should follow a Capability Maturity Model Framework:

- Category A (Mission-Critical, Non-Negotiable): Flight control system, stealth shaping, sensor fusion, active electronically scanned array (AESA) radar, and integrated electronic warfare (EW) suite.

- Category B (Performance Enhancers, Prioritized but Iterative): Supercruise capability, optimized weapons bay, and adaptive power management.

- Category C (Deferred Enhancements for Block Upgrades): Laser weapons, high-energy propulsion augmentation, and AI-driven combat decision support.

Technology Insertion Roadmap

India should develop the AMCA through a Block 1, Block 2, and Block 3 approach. This phased method ensures that capabilities improve gradually without delaying initial production. A Milestone Decision Authority should oversee these phases, ensuring timely progression.

3. Securing a Reliable Jet Engine

Short-Term Plan

India must establish a Parallel Engine Procurement and Indigenous Augmentation Framework. This approach reduces risks associated with dependence on foreign suppliers. In the short term, India should secure a reliable powerplant such as:

- An enhanced AL-31F

- General Electric F414

- Other available derivative variants

Long-Term Plan

Developing an indigenous Kaveri-derived engine should be a top priority. This engine must integrate:

- Single-crystal turbine blades

- Adaptive cycle technology

- Ceramic matrix composites

A co-development agreement with an OEM such as Rolls-Royce, Safran, General Electric, or Pratt & Whitney can ensure that India maintains full control over propulsion technology. Transfer of Design Rights should be part of this agreement to secure sovereign propulsion capability.

4. Speeding Up Prototyping and Flight Testing

Rapid Development Strategy

A Fly Before Freeze paradigm will ensure that an Engineering Demonstrator Vehicle is airborne within 12 to 15 months of program initiation. This approach prevents excessive delays in early testing.

Essential Testing Mechanisms

India must integrate a Rapid Prototyping and Experimental Validation Framework that includes:

- Iron Bird Test Rig: Simulates avionics and flight control software before actual testing.

- Incremental Airworthiness Certification Model: Allows phased approvals instead of waiting for a monolithic final system qualification.

5. Modular Subsystem Development

Open Systems Architecture

Adopting an Open Systems Architecture will help separate avionics and mission system development from the airframe timeline. Engineers should freeze the core structural design and propulsion interface while using dummy payloads for unfinalized subsystems. These include:

- Directional Infrared Countermeasures

- Infrared Search and Track

- Missile Approach Warning Systems

- Gallium Nitride-based AESA radar upgrades

Plug-and-Play Capabilities

A modular plug-and-play system allows subsystems to be integrated in parallel without delaying serial production. This flexible approach minimizes the risk of bottlenecks.

6. Implementing a Rolling Production Model

Iterative Upgrades

India should adopt a Rolling Upgrade Doctrine, where software and hardware upgrades happen continuously without grounding the fleet. A Frozen Outer, Fluid Inner approach will keep aerostructural elements stable while allowing future avionics and sensor upgrades.

Model-Based Systems Engineering

Using Model-Based Systems Engineering can synchronize design, testing, and production. This method reduces rework costs and ensures a smoother transition between development phases.

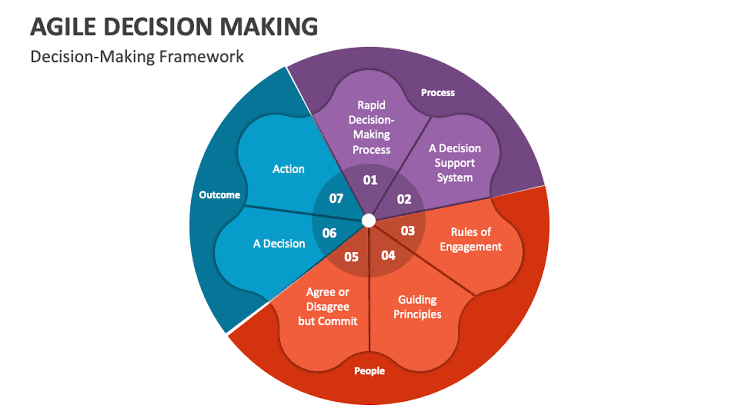

7. Strengthening Decision-Making and Accountability

Agile Decision-Making Framework

A High-Velocity Decision-Making Framework will prevent bottlenecks. Decentralized decision-making ensures that minor approvals do not delay the program. A Fail Fast, Fix Faster culture should be encouraged to resolve technical failures within a 12-month period.

Leadership Accountability

Establishing a Decision-Making Doctrine ensures discipline in leadership. Field Marshal Sam Manekshaw’s famous words should be displayed prominently: “If you want to be a bloody fool, be one quickly.” This statement reinforces urgency and accountability.

8. Transparent Progress Tracking

Regular Status Conferences

The AMCA program should hold Monthly Status Conferences covering:

- Achieved technical milestones

- Current bottlenecks and mitigation strategies

- Short-term and long-term goals

Stakeholder Engagement

India must maintain public confidence and political buy-in. The program should provide controlled media updates, similar to NASA Artemis briefings or Lockheed Martin F-35 progress reports.

Independent Oversight Panel

A specialized Independent Oversight Panel should ensure program accountability. This panel should include:

- Test pilots from the Indian Air Force Test Pilot School

- Systems engineers from HAL, ADA, and DRDO

- Industrial manufacturing specialists

I do not claim to have all the answers, but my recommendations come from years of industry experience and close monitoring of defense programs. As said before this is based on a question from an X user and a lot of this is already done by authorities involved in AMCA Program. The paramount need is “a time-bound, structured approach” will ensure that AMCA does not face the delays that plagued previous indigenous fighter projects. India must integrate concurrent design, rapid prototyping, advanced manufacturing, and disciplined decision-making. With the right strategy, AMCA will emerge as a world-class fifth-generation fighter, setting new benchmarks in indigenous aerospace development. I hope this answers few questions.

Simply Great