India is preparing to mark a milestone in its aerospace journey. Larsen & Toubro (L&T) has completed the first pair of wings of Tejas manufactured entirely outside the public sector. The company is now awaiting an official handover event. This will mark the first time a private Indian firm delivers this critical flight structure.

Wings of Tejas Enter Private Manufacturing with L&T’s First Completed Pair

L&T has successfully finished building the wings of Tejas, meeting all quality and structural requirements. Final delivery is now pending a ceremonial event, expected to be a landmark occasion for Indian aerospace. Until now, only HAL held the capability to manufacture wings for fighter aircraft. This transition to private industry signals a major shift in production strategy.

Wing Manufacturing Involves Complex Processes

Jet aircraft wings are complex and flight-critical. They bear aerodynamic loads, carry fuel, and house pylons and control linkages. The Tejas wings, made from advanced composites, demand precision and advanced tooling. L&T used technologies like automated fiber placement, autoclave curing, and ultrasonic drilling to meet stringent aerospace standards.

Building wings involves more than structural integrity. Each wing integrates hydraulics, fuel lines, and control surface fittings. The margin for error remains minimal. L&T’s manufacturing ability to deliver indicates its growing engineering maturity and alignment with global aerospace manufacturing standards.

HAL’s Modular Strategy Powers Private Participation

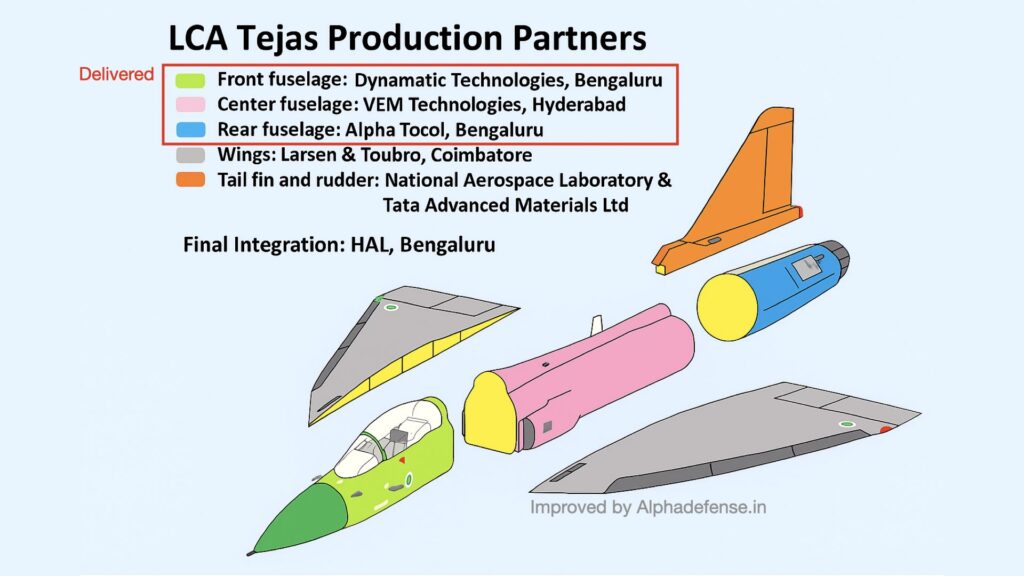

HAL has adopted a modular production strategy for Tejas Mk1A. Under this plan, major fuselage sections come from private vendors. Dynamatic Technologies builds the front fuselage. VEM Technologies produces the mid-section. Alpha Tocol fabricates the rear fuselage. Tata Advanced Systems manufactures the tailfins and rudders.

Now, with L&T joining by delivering the wings, nearly the entire airframe structure comes from private sector partners. HAL remains the final integrator. It oversees assembly, testing, and certification at its Bengaluru & Nasik facility.

Rear fuselage by Alpha Tocol

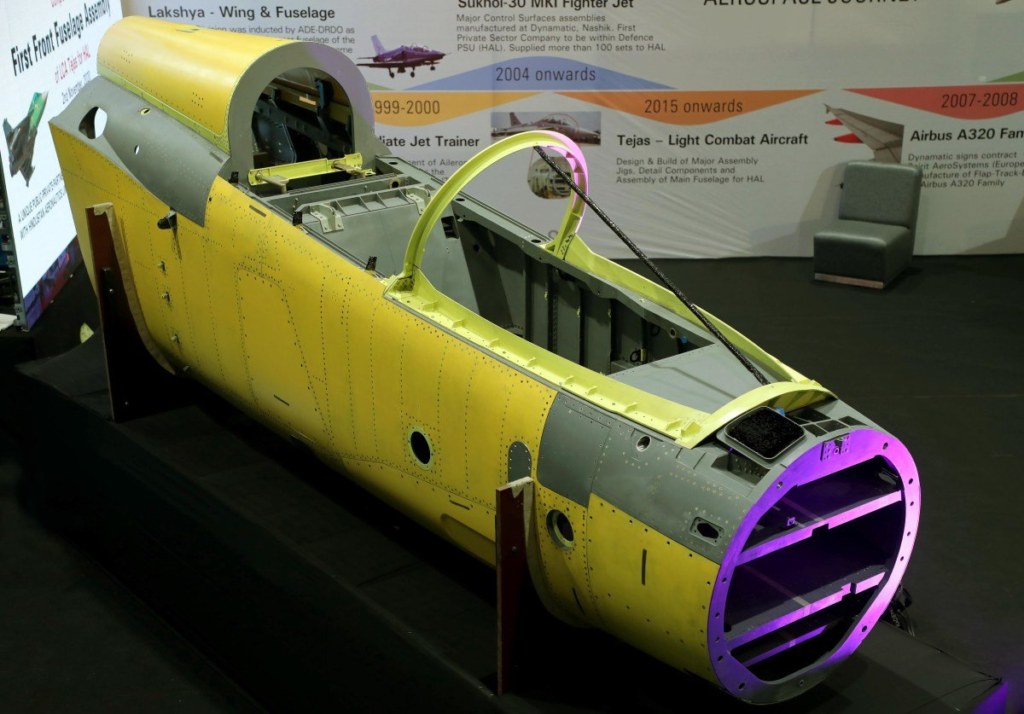

Frontal Fuselage from Dynamatic Technologies

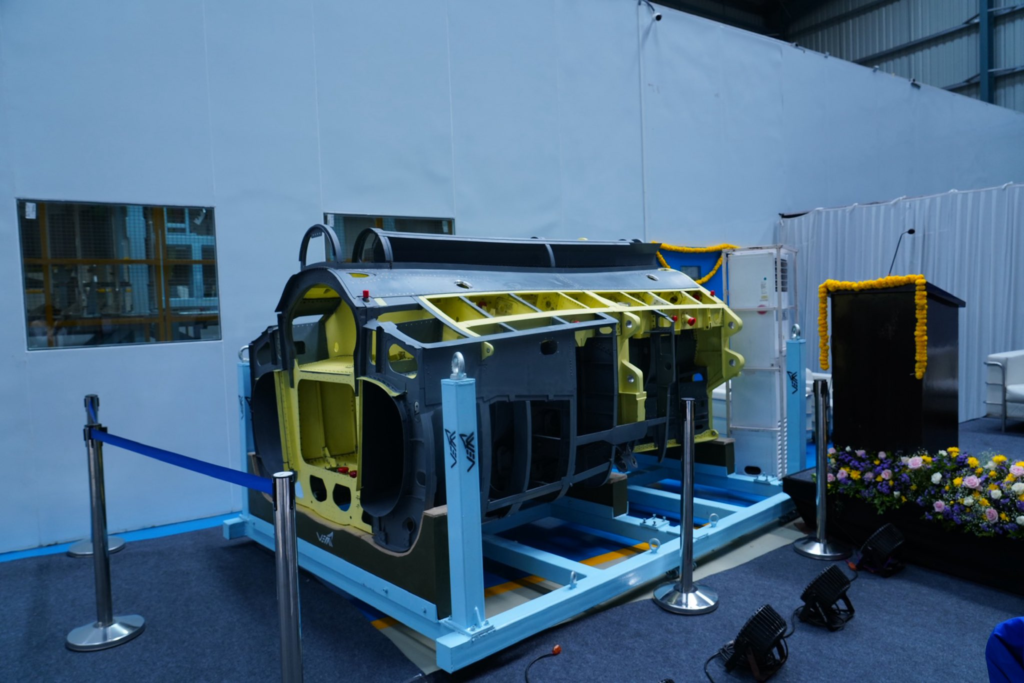

Center fuselage by VEM Technologies

L&T’s Role Marks a Turning Point

L&T’s achievement shows that Indian private firms can handle highly complex aerospace assemblies. Building wings involves tight tolerances, critical system routing, and long-duration structural integrity. With its first pair ready, L&T has proven its facility and workforce are capable of next-generation defense manufacturing.

This development aligns with India’s broader goals under Make in India and Atmanirbhar Bharat. It also opens doors to future participation in high-value projects like AMCA and TEDBF.

Strategic Benefits of Private Wing Production

Private-sector involvement boosts production capacity and reduces the burden on HAL. The Indian Air Force needs faster delivery of Tejas Mk1A fighters. With wings coming from L&T, HAL can accelerate integration and final assembly.

The move also strengthens India’s aerospace supply chain. It spreads technical know-how across industry.

Overall, The first privately built wings of Tejas are now ready for handover. L&T awaits the right moment to formally deliver them. When that happens, it will mark a defining moment for Indian aerospace. For the first time, a flight-critical structural component will enter service from a private production line. This transition represents not just a shift in manufacturing but a leap toward industrial self-reliance and scalability.

One thought on “L&T Prepares First Private-Sector Wings of Tejas”