Donald Trump, in his characteristic bluntness, recently stated, “We want to sell engine weapons worth billions and billions of dollars, we are working on to make sure India eventually have F-35 stealth fighter.” The key word here—eventually—immediately raises critical questions about the path India must navigate before these jets are offered. Was Trump referring to clearance hurdles at multiple levels within the U.S. administration? Or was this a nod toward Lockheed Martin’s long-standing proposal, which initially linked the F-35 acquisition to the assembly of F-16 variants (rebranded as F-21) in India under the Multi-Role Fighter Aircraft (MRFA) program?

This statement reignites concerns about past U.S. proposals that have always tied the F-35 to the F-21 offer—before India proceeded with the S-400 acquisition. While much of the national debate revolves around whether India should or shouldn’t acquire the F-35, the real concern lies in the potential technological repercussions of such a procurement strategy.

Manufacturing Paradigm Shift: Traditional vs. Next-Gen

The F-16 (and by extension, the F-21) is currently manufactured at Lockheed Martin’s Greenville, South Carolina facility, a production line shifted from Fort Worth, Texas, to make room for expanded F-35 Lightning II production. The Fort Worth assembly line, established in 1975, rolled out its first F-16A in October 1976. While incremental improvements have been made, the underlying manufacturing philosophy remains anchored in traditional machining and casting—technologies that have now been largely superseded.

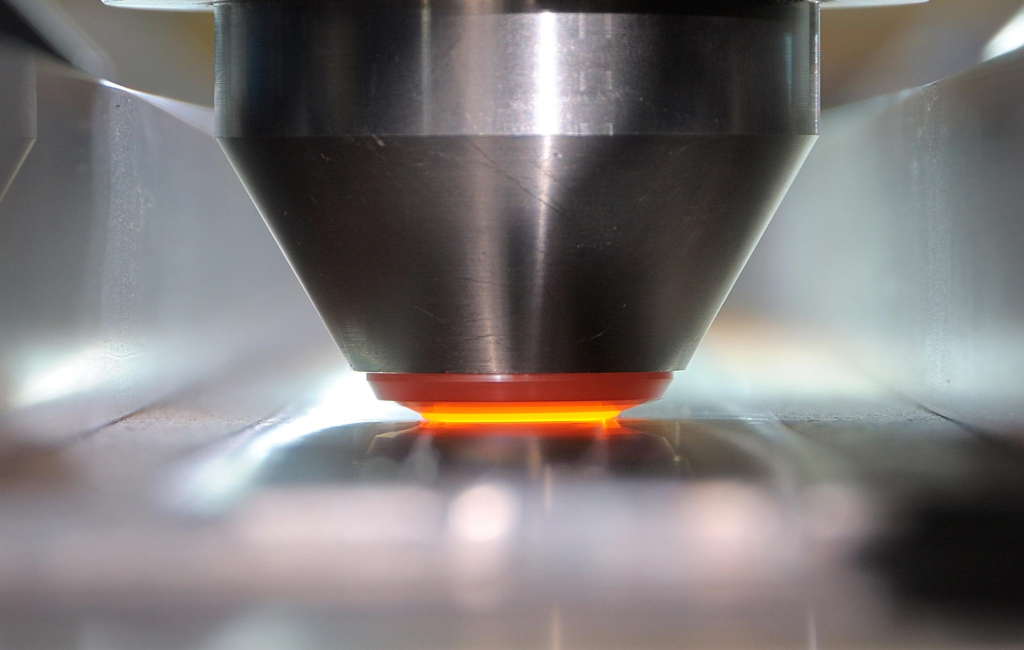

The aerospace industry has moved towards Additive Manufacturing (AM) and high-precision automation. Friction Stir Welding (FSW) has revolutionized structural integrity by enabling seamless joints without compromising material strength. The F-35, in contrast to the F-16, is produced on a highly automated pulse-line manufacturing system—similar to high-end automotive production. This enables greater efficiency, precision, and scalability, ensuring that aircraft can be produced at a significantly faster rate while maintaining stringent quality standards.

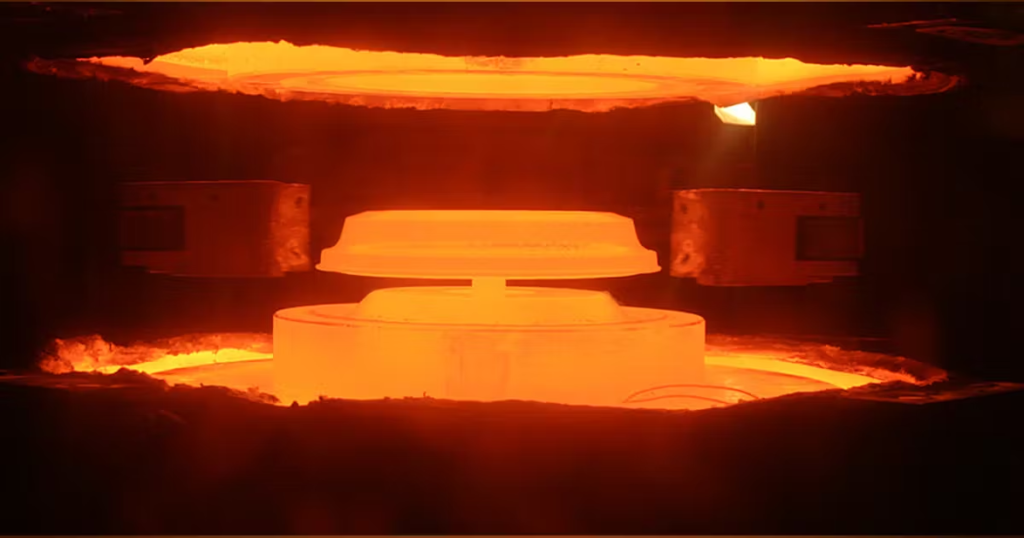

Another transformative advancement in aerospace manufacturing is the shift from traditional machining to isothermal forge pressing. Bulkheads produced using this method enable airframes to withstand significantly higher stress and strain, making them suitable for more powerful engines and next-generation flight envelopes.

The Technological Regression of an F-21-F-35 Transition

If the F-21 is indeed being positioned as a stepping stone to the F-35, then India risks being funneled into an outdated manufacturing ecosystem. Indian industry, which could potentially leapfrog into cutting-edge techniques such as Wire Arc Additive Manufacturing (WAAM), Selective Laser Melting (SLM) / Electron Beam Melting (EBM), Isothermal Forging, Superplastic Forming & Diffusion Bonding (SPF/DB), and Friction Stir Welding (FSW), might instead be forced to adopt legacy machining and casting techniques from Greenville’s F-16 assembly line.

This presents a critical inflection point. India’s private sector has the potential to outperform traditional public sector units like HAL by leveraging state-of-the-art infrastructure and highly skilled manpower. However, if the F-21 deal locks India into older assembly methodologies, it could derail technological progress, anchoring the country’s aerospace sector to an outdated industrial base.

The strategic decision, therefore, is not just about whether to procure the F-35 but about whether the pathway to that acquisition aligns with India’s vision of becoming a global aerospace manufacturing hub. If the price of entry into the F-35 program is a technological downgrade, then policymakers must scrutinize whether such an approach truly serves national interests.

In the pursuit of modern fighter platforms, India must ensure that it is not just acquiring jets but also securing the cutting-edge manufacturing capabilities that will define aerospace superiority in the decades to come.

Nice article

I don’t think government will go for Fcuk 16 or 21.

हमें मात्र 54 / 57 SU57 AL51 इंजन व स्वदेशी वीरूपक्ष राडार संग लेना चाहिए ।

114 MRFA समाप्त करना चाहिए ।

इससे AMCA 170 , तेजस MK1A 83+97, MK2 170 व TEDBF 65 का मार्ग प्रशस्त होगा।

बचत से कावेरी 90 KN व 115 KN बनाना चाहिए ।